The Importance of High-Quality Cables in Efficient Power Transmission

Cables, designed and used to transmit electrical current efficiently, are insulated wires covered with a protective material. Depending on their purposes and applications, there are numerous types of cables available on the market. The primary goal of cables is to transmit electrical energy from one point to another with minimal power loss. This is achieved by producing single or multi-core conductors in various types and specifications, which can be either insulated or bare electrical connection elements.

The production of cables takes into consideration environmental factors such as underground installation, liquid contact, varying weather conditions, and both mobile and stationary use. To ensure that environmental and electrical factors do not negatively impact power transmission, cables are equipped with protective layers surrounding the conductors for power, communication, and control applications.

Cables can be classified based on the materials used in their production, such as copper and aluminum conductor cables. Copper and aluminum are commonly used as conductors in power cables due to their cost-effectiveness. Cables can also be categorized according to their use as either low-current or high-current cables. One of the most frequently used cable types in recent years is NYY cables, which are defined as PVC-insulated, low-voltage power cables.

The rapid advancements in technology have made the selection criteria for cables and their impact on human health critically important. The choice of low-current cables, often used in indoor applications for buildings, is particularly crucial. These cables, operating below 1kV, are typically used for sound, telephone, video, alarm, data, CCTV, and security systems in buildings. Low-voltage cables fall under the category of low-current cables and are expected to have specific features based on their use and purpose. NYY cables are preferred in areas with high human traffic or valuable assets, such as semi-smart and smart buildings, cinemas, schools, airports, hospitals, theaters, shopping centers, factories, and tunnels, due to their properties like non-flammability, low smoke density, and absence of corrosive and harmful gases.

Additionally, the correct selection of sheathing or the need for armoring is critical for cable performance in environments with risks such as impact, strain, or rodent presence. Cables may require protective features against elements like oil, moisture, and chemicals in the environment. If there is another signal that could interfere with the transmitted signal, shielding might be necessary. The type of shielding required should be determined by experienced and competent individuals based on the environment and signal characteristics. Ensuring the desired quality of shielding involves paying close attention to the braid coverage ratios.

NYY cables, as low-voltage cables, come in various types. Single-core versions can be produced with single-wire cores up to 10 square millimeters and multi-wire cores up to 300 square millimeters, insulated with a protective sheath. For multi-core versions, single-wire cores are available up to 10 square millimeters, and larger cross-sections are multi-wire. NYY cables feature a common sheath over twisted cores and a black outer sheath.

The permissible operating temperature for NYY cables is 70°C, with a short circuit temperature of 160°C. They have a test voltage of 2kV, a minimum laying temperature of -5°C, a maximum conductor temperature of 70°C, and a rated voltage of 0.6/1kV.

While NYY cables share some similarities with NYM cables, NYM cables are only used for surface installations, whereas NYY cables can also be laid underground. It is important to note that multiple single-core NYY cables should not be passed through steel pipes, as this can create a capacitor effect, causing insulation to melt in a short time.

Single-core NYY cables are insulated wires covered with a protective sheath. These cables can be easily used in areas without significant mechanical strain due to their heat-resistant structure. They are suitable for applications without mechanical strain, such as power stations, network lighting, indoor installations, general construction cables, cable channels, industrial facilities, conduits, and pipes.

NYY cables can be used as energy cables underground, outdoors, indoors, in fresh water, cable channels, underground, in power plants, switchgear, energy facilities, and, when specially manufactured, in saltwater. However, it is crucial to select the appropriate type based on the application and purpose.

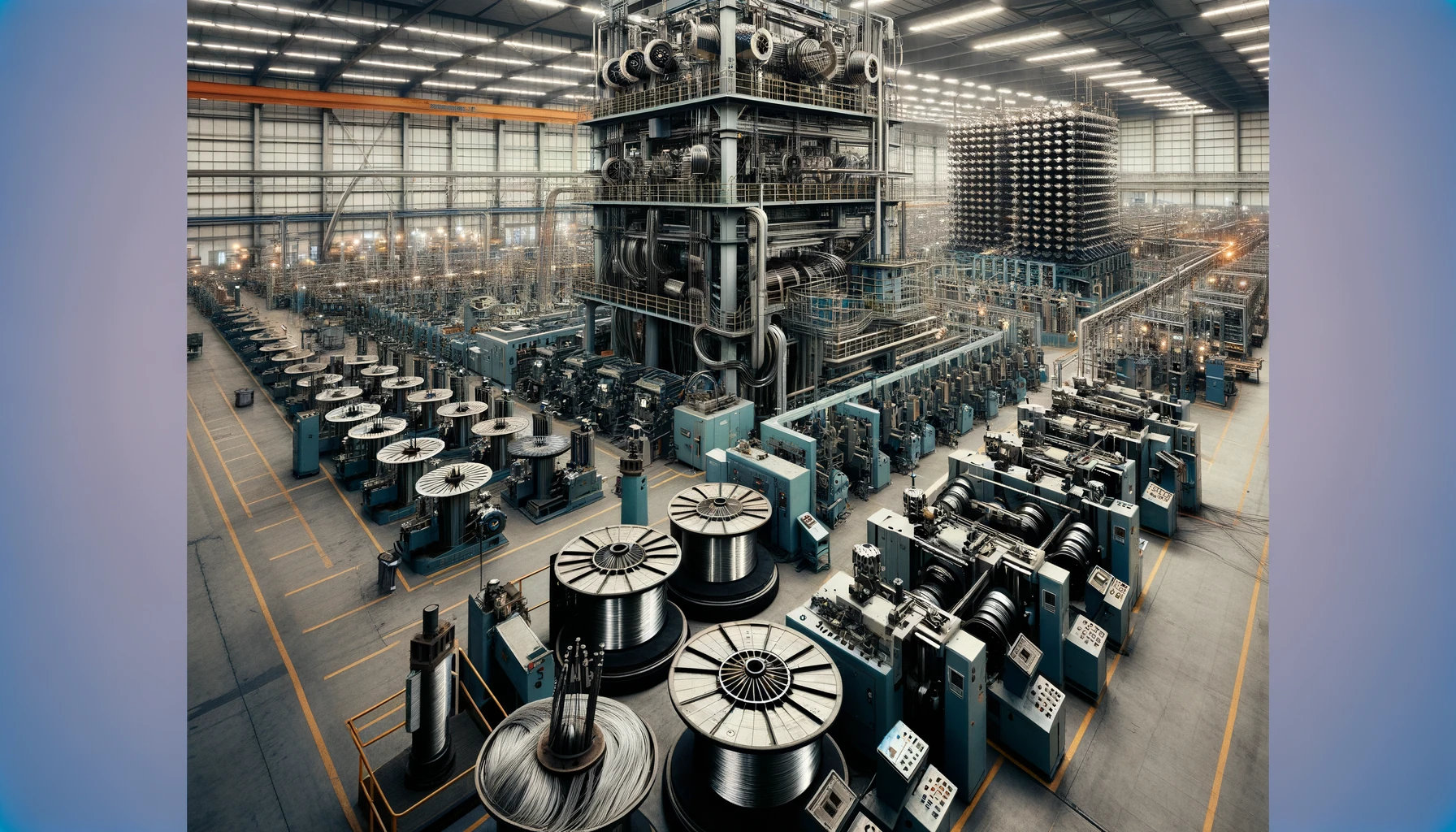

Intekar Global is cable factory based in Macedonia.